A brief discussion on the differences between coreless motors and coreless brushless motors? Which one has the advantage?

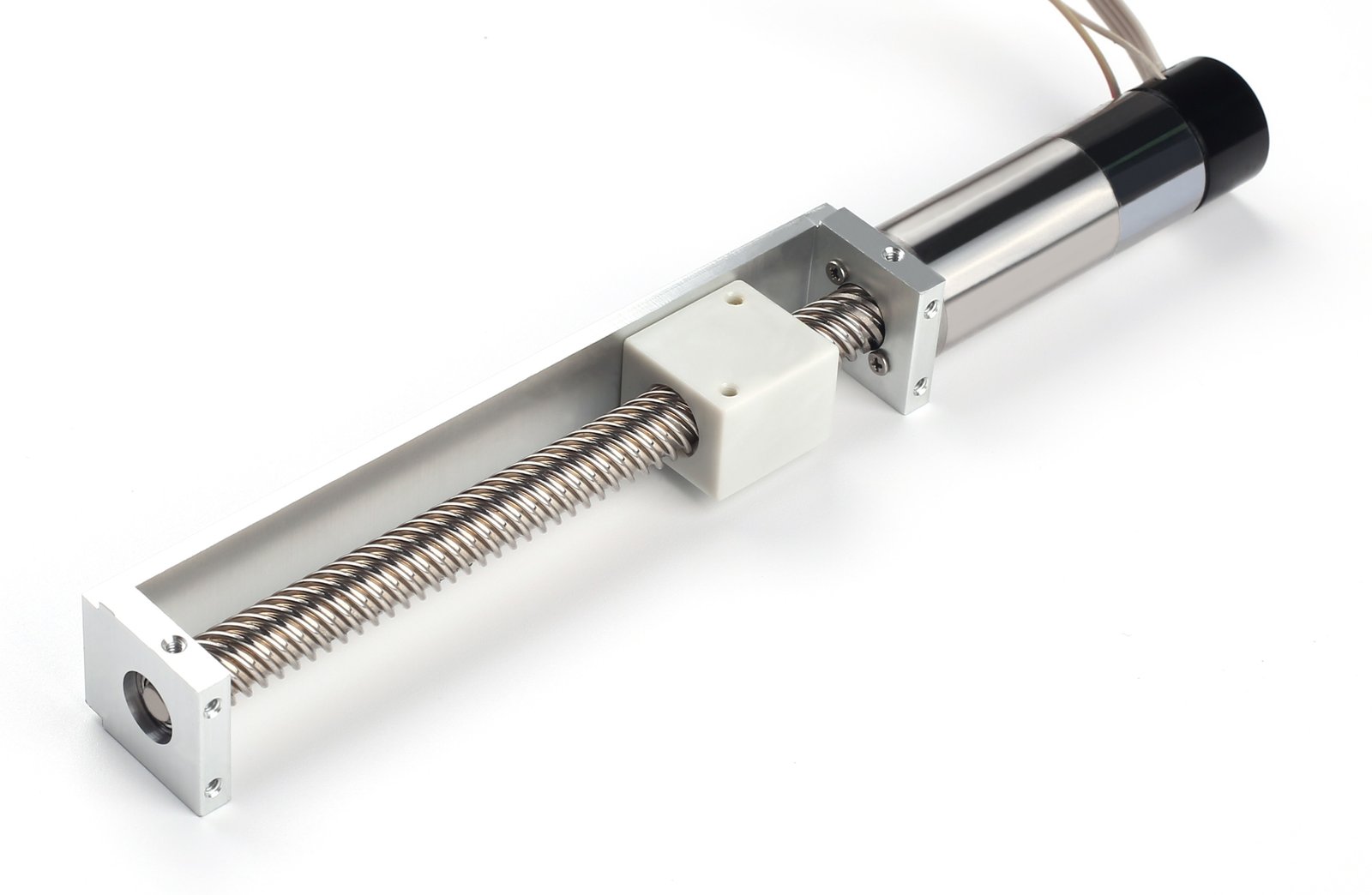

Coreless motors fall under the categories of permanent magnet motors, DC motors, and servo micro motors. They exhibit excellent energy-saving characteristics, flexible and simple control, and stable operation. As a high-speed energy conversion device, coreless motors represent the future direction of motor development. By breaking away from the traditional rotor structure, they utilize a coreless rotor design. Next, let’s explore with WKX MOTOR the differences between coreless motors and coreless brushless motors, and which one is better.

1. Differences Between Coreless Motors and Coreless Brushless Motors

Coreless motors can be divided into brushed and brushless types. The coil in coreless motors adopts a cup-shaped structure. In brushed motors, the coreless coil serves as the rotor, while in brushless motors, the coreless coil acts as the stator. Brushless motors utilize Hall sensors for electronic commutation.

2. Which is More Advantageous: Coreless Motors or Coreless Brushless Motors?

Coreless brushless motors are superior. A brushless DC motor consists of the motor body and a driver, forming a typical mechatronic product. Brushless motors lack brushes and commutators (or slip rings), earning them the name "commutatorless motors."

This concludes the overview of the differences between coreless motors and coreless brushless motors. For more information, please contact Shenzhen WKX MOTOR Co., Ltd.