How to solve the heating problem of micro DC motors?

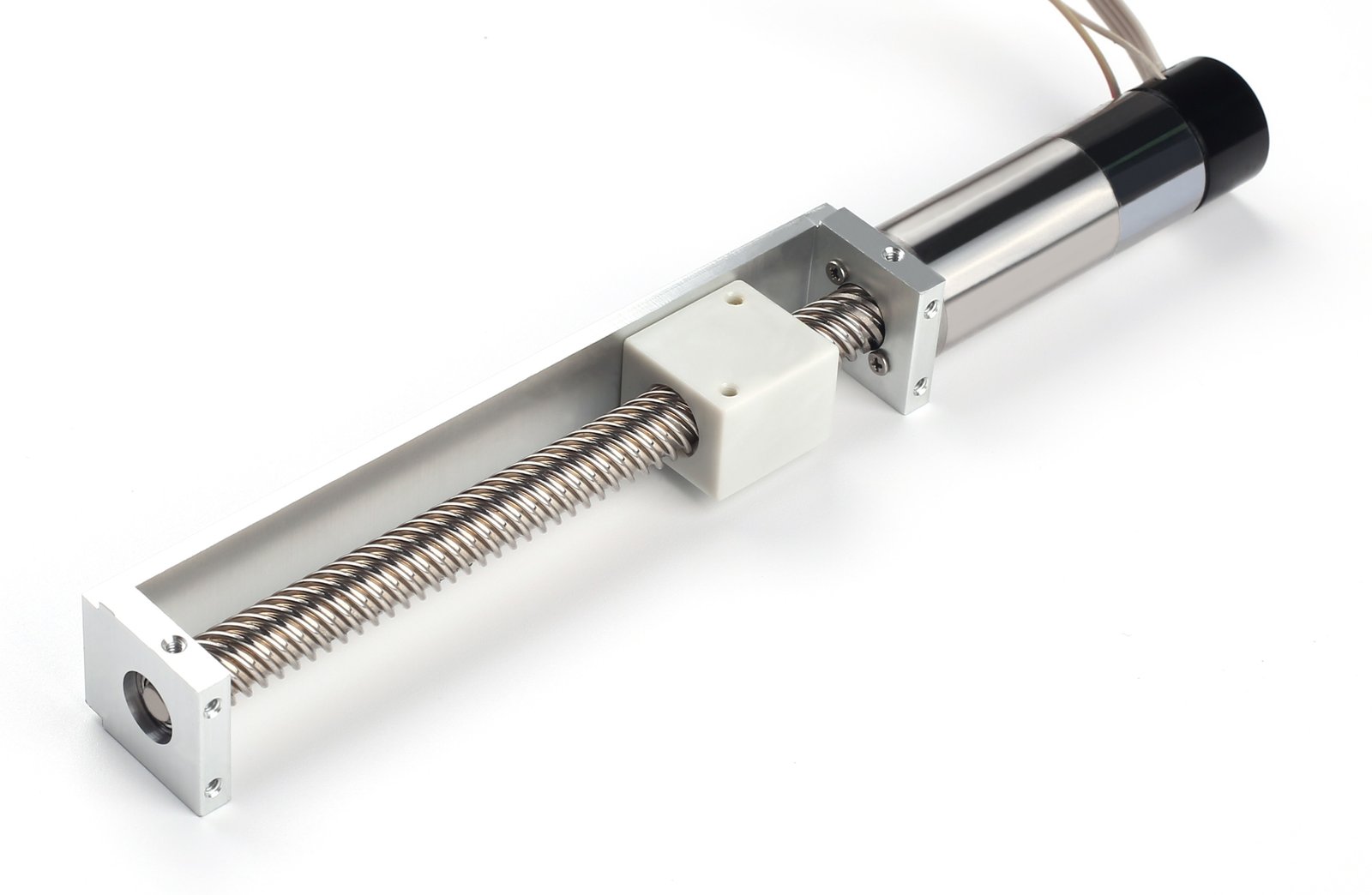

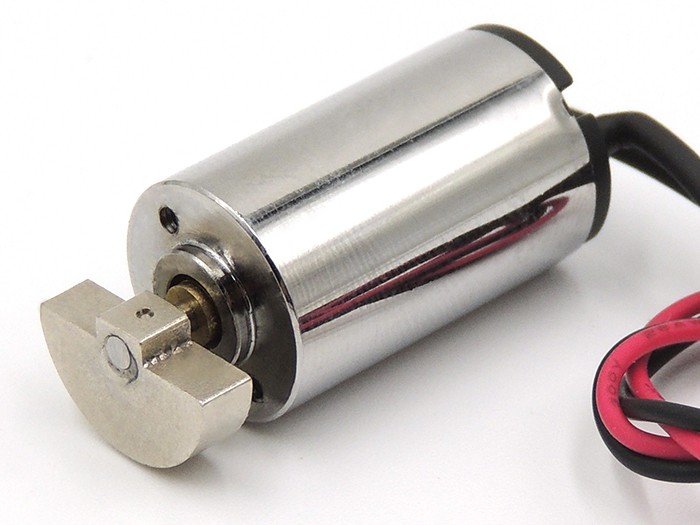

Many customers find that when coreless gear motors are installed and operated for extended periods, the temperature becomes relatively high, especially when the input speed of the micro motor is too fast, causing the heat to increase significantly.

1. Overloading of Micro DC Motors (Planetary Gear Motors) Micro DC motors, also known as planetary gear motors, often experience overheating when the load exceeds the manufacturer's specified rated load. This occurs because excessive load causes the internal gears of the gear reducer to mesh tightly, increasing friction and resulting in a significantly higher load.

2. Incompatibility of Internal Structure with Input Speed Some customers have reported that when the same motor is paired with the same gear reducer but with different reduction ratios, the noise and heat generated vary. What causes this difference?

Through effective testing and analysis, we found that gear reducers with more severe heating issues tend to have a larger primary sun gear at the input end. In this case, the sun gear operates in a deceleration mode, while the planetary gears operate in an acceleration mode, naturally leading to greater heat generation.

Solutions to Address This Issue To mitigate such problems, it is recommended to use a gear reducer with a different reduction ratio or to modify the internal gear structure (though this is more costly).

Of course, with numerous coreless motor manufacturers and varying industry standards, the primary reasons for gear reducer overheating generally boil down to the two points mentioned above. For more information, please contact Shenzhen WKX MOTOR Co., Ltd.