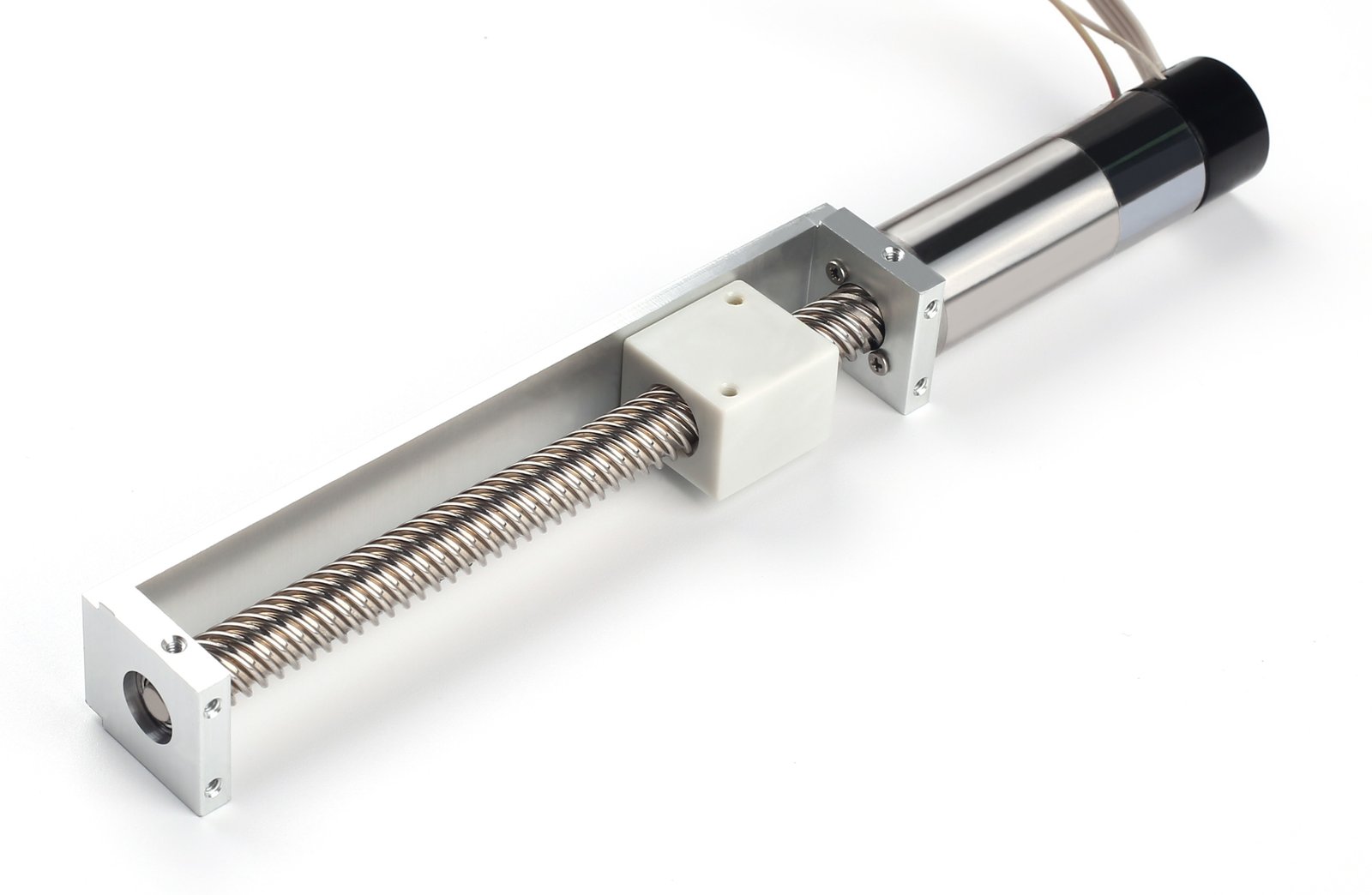

How to protect a coreless gear motor from damage?

How to protect a coreless gear motor from damage? Regular maintenance is crucial for reducing and preventing failures of coreless gear motors during operation. The most important aspect is routine inspections and promptly addressing the root causes of any abnormal phenomena. To ensure that coreless gear motors are not damaged under various conditions, certain operational protection measures must be implemented.

Measures to Protect Coreless Gear Motors from Damage:

1. Keep the Motor Clean Ensure that no water droplets, oil, dust, or other contaminants enter the interior of the gear motor, and regularly clean dust from both the inside and outside of the motor.

2. Monitor Temperature Rise Ensure that the temperature rise of the coreless gear motor does not exceed its rated value.

3. Control Load Current Ensure that the load current does not exceed the rated value.

4. Inspect Bearings Check for bearing overheating or oil leakage, and ensure regular lubrication as specified.

This concludes the comprehensive guide from WKX MOTOR on “How to protect coreless gear motors from damage?” We hope this information is helpful to you!