Why do coreless DC motors require a controller to regulate motor speed and output torque?

The coreless DC motor controller is a special type of electrical device that converts electrical energy into mechanical energy. Coreless DC motors receive electrical energy through direct current and then convert this energy into the motor's automatic rotation. Coreless DC motors are nearly ubiquitous, utilizing the magnetic field generated by the current to drive the rotor fixed to the output shaft. The speed and output torque depend on the motor’s design and the electrical input.

How Does a Coreless DC Motor Controller Work?

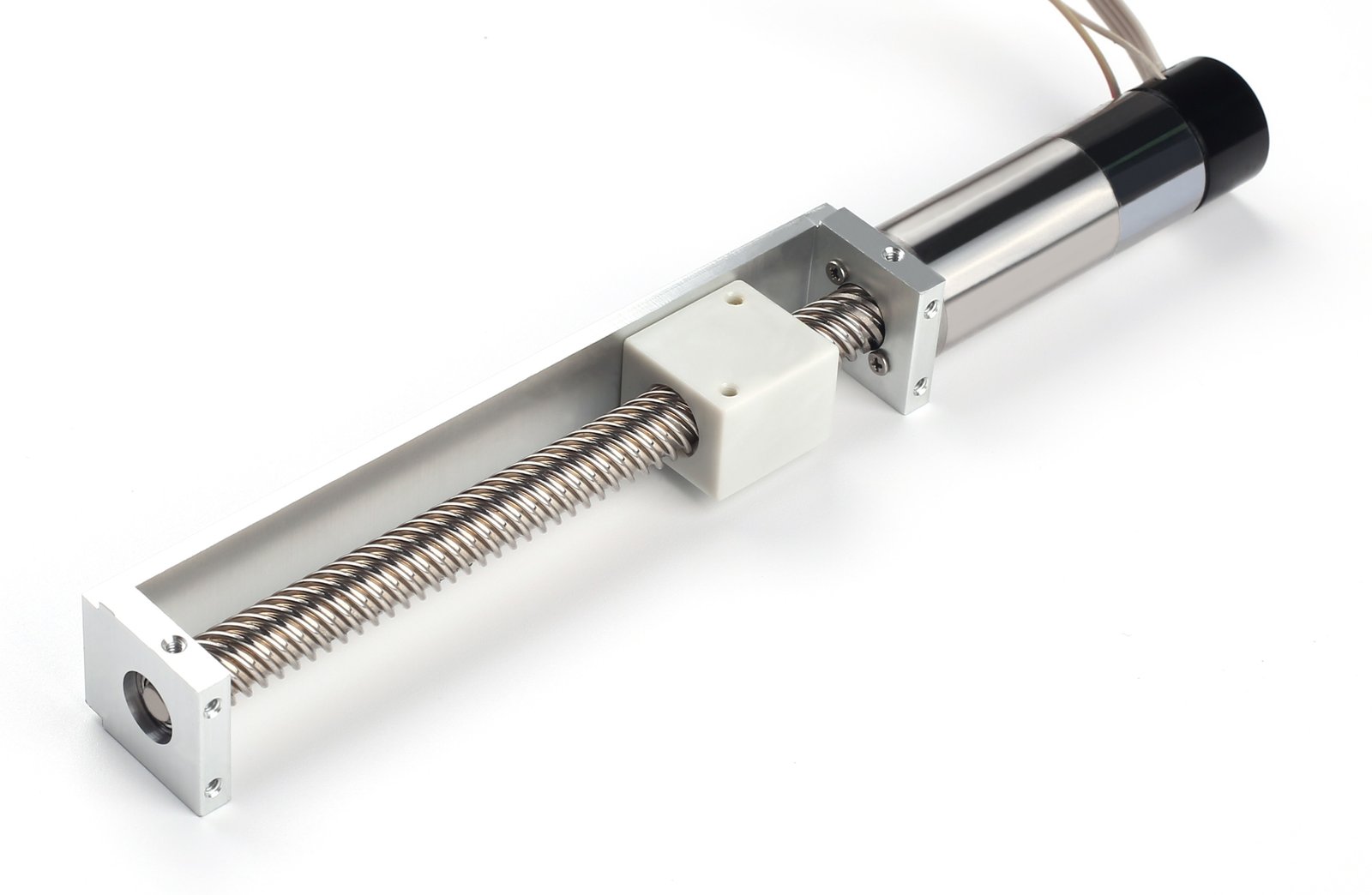

Coreless DC motors vary in power and size and can be used in various mechanisms, such as electric hoists, elevators, electric vehicles, and toys. A coreless DC motor consists of two basic components: the armature and the stator. The stator is the stationary part of the motor, while the armature is the rotating part. In addition to using coils, coreless DC motors utilize a set of fixed magnets in the stator. When current flows through the circuit of insulated wires, it generates an aligned electromagnetic field. One or more coil windings of insulated wire are wrapped around the motor’s core to concentrate the magnetic field. These windings are connected to a rotating electrical switch (commutator), which continuously applies current to the coil windings. The rotating electrical switch energizes each armature coil in sequence, generating torque or a consistent rotational force. As the coils are turned on and off in sequence, a magnetic field is created that interacts with different regions of the fixed magnets, producing torque. These fundamental operating principles allow coreless DC motors to convert electrical energy from direct current into mechanical energy for driving devices, achieved through rotational motion.

Considerations Before Purchasing a Coreless DC Motor

Before purchasing a coreless DC motor, several key factors should be considered:

Energy and Torque: Higher energy results in greater torque. The energy ensures that the net current flows in a single direction. Check the recommended pulling force of the coreless DC motor in the user manual.

Current: Current powers the motor, but excessive current can be dangerous and damage the motor. Before using a coreless DC motor controller, ensure you understand its operating current and stall current.

Speed: Motor speed can be complex. Motors operate efficiently at high speeds, but this efficiency may not hold if gear transmission is required, as adding gears does not limit motor efficiency. Therefore, both torque and speed reduction need to be considered.

Why Choose Coreless DC Motors?

When the option to use AC motors is available, coreless DC motors are strongly recommended due to their advantages over AC motors. For instance, they are excellent for applications requiring high starting torque to drive high-inertia loads. Unlike AC motors, coreless DC motors are easy to control in terms of speed.

Coreless DC motors are also ideal when powered by low-voltage DC sources, such as solar panels or batteries. If rapid direction reversal is needed, coreless DC motors are highly suitable. Unlike AC motors, coreless DC motors can be easily and quickly started and stopped.

Application Areas of Coreless DC Motor Controllers

Various coreless motors are available on the market today. Coreless DC motors are used in toys, tools, and other household appliances. In industrial applications, they are employed in operations ranging from turntables to conveyor belts and for reversing tasks. Due to their excellent motion responsiveness and ease of speed variation, coreless DC motors are used to power pumps. Their energy-saving mechanisms make them the preferred choice for fans. Coreless DC motor toys come in various voltages, requiring different types of motion and speeds. They are preferred for electric vehicles due to their durability and energy efficiency. Coreless DC motors are installed in the rear and front wheel hubs of electric bicycles to achieve the required power levels and torque.