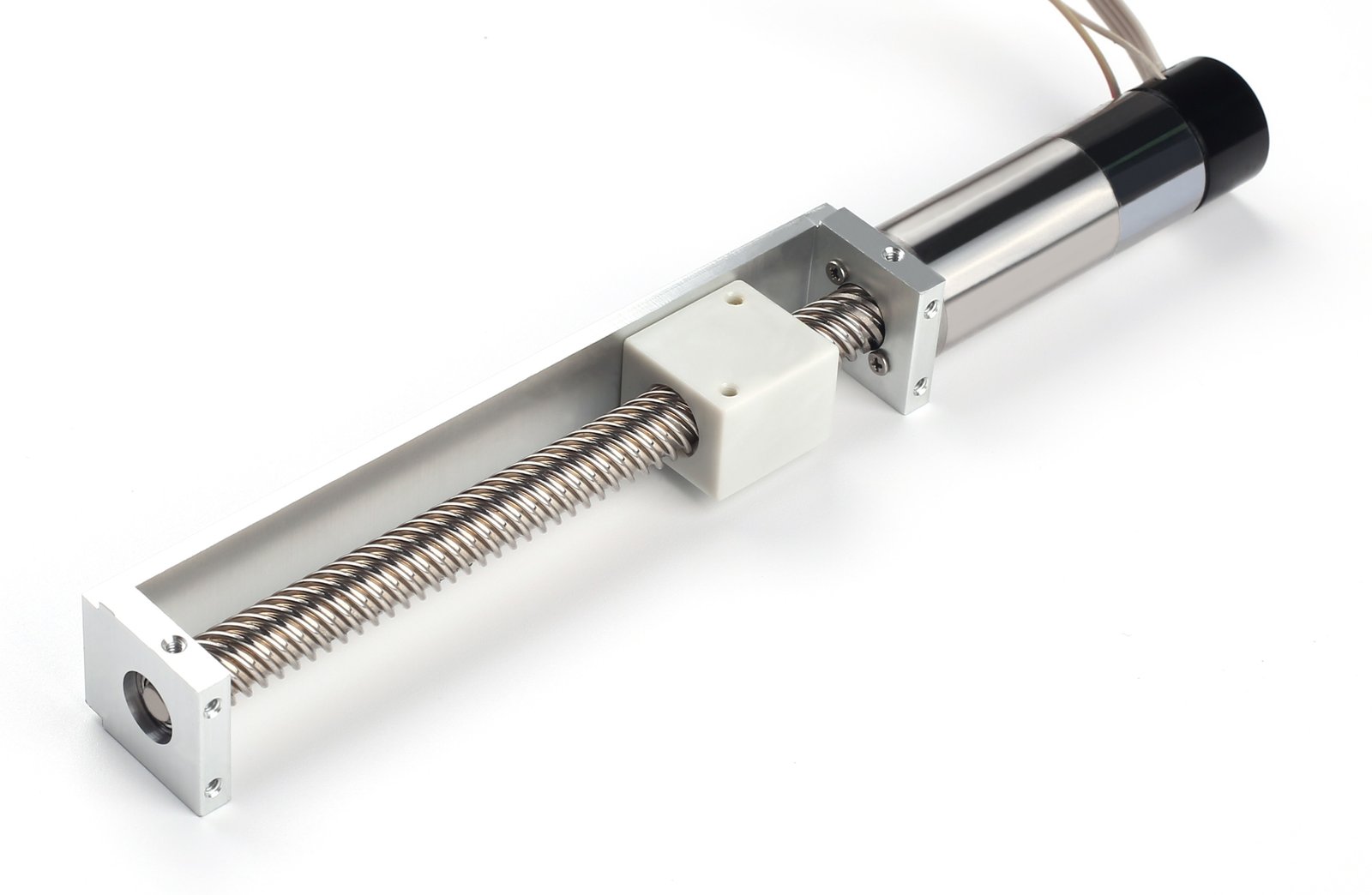

What are the advantages and disadvantages of a coreless hollow cup micro motor?

Compared to ordinary DC motors, coreless micro DC motors use a coreless rotor, offering the advantages of a smaller size and lighter weight. WKX Motor briefly outlines the advantages and disadvantages of hollow cup micro DC motors:

Advantages of Coreless Hollow Cup Micro Motors:

1. High Power Density**: The power density of a hollow cup micro DC motor, defined as the ratio of output power to weight or volume, is high. The coreless rotor is lighter than a traditional iron-core rotor. The absence of a core eliminates eddy current losses in the iron-core rotor, reducing hysteresis losses, which improves the efficiency of the micro motor, ensuring higher output torque and power.

2. High Efficiency**: The high efficiency of micro motors stems from the absence of eddy current and hysteresis losses in the coreless rotor, along with low resistance, which reduces copper losses.

3. No Torque Hysteresis**: The coreless rotor has no loss-related hysteresis, reducing fluctuations in speed and torque.

4. No Cogging Effect**: Ordinary micro motors exhibit a cogging effect due to the interaction between slots and magnets, whereas coreless DC motors eliminate this effect, preventing both cogging and torque hysteresis.

5. Low Starting Torque**: Due to the absence of hysteresis losses and cogging effects, the starting torque is very low, with bearing load typically being the only obstacle.

6. No Radial Force Between Rotor and Stator**: DC motors without an iron-core rotor lack radial magnetic forces between the rotor and stator. In some applications, radial forces between the rotor and stator can cause rotor instability, and reducing these forces enhances rotor stability.

7. Smooth Speed Curve and Low Noise**: The coreless rotor reduces harmonics in torque and voltage. Since there is no alternating magnetic field in the micro motor, there is no AC noise—only noise from bearings, bearing-related vibrations, and non-sinusoidal current-induced airflow vibrations.

8. High-Speed Coil**: The inductance parameter is crucial for micro motors operating at high speeds. A low inductance value allows for a lower starting voltage. Increasing the number of poles and reducing the casing thickness can help lower the inductance value, improving micro motor performance while simultaneously increasing power density.

9. Fast Response**: Due to the low inductance of the micro motor, the current responds quickly to voltage fluctuations. With a low rotor moment of inertia, the response time of torque and current is significant, making the rotor's acceleration approximately twice that of an ordinary iron-core motor.

10. High Peak Torque**: The ratio of peak torque to continuous torque in micro motors is large. Since the torque constant remains unchanged as the current rises to its peak, the linear relationship between current and torque allows micro motors to generate higher peak torque. In contrast, once an ordinary iron-core DC motor reaches saturation, increasing the current does not increase the torque.

11. Good Heat Dissipation**: The hollow cup rotor surface allows for better airflow compared to an iron-core rotor, improving heat dissipation. In iron-core rotors, enameled wires are embedded in silicon steel slots, resulting in limited surface airflow and higher temperature rise. Under the same power output conditions, the temperature rise of a hollow cup DC motor is lower.

Disadvantages of Coreless Hollow Cup Micro Motors:

Coreless hollow cup micro motors have a drawback when stationary. If one phase of the winding is cut off or the power supply to one phase is interrupted while connected, the magnetic fields generated by the windings are equal in magnitude but opposite in direction, creating rotating magnetic fields. The torques resulting from their interaction with the rotor are equal in magnitude but opposite in direction, canceling each other out. This results in zero starting torque, preventing the motor from starting, which is a limitation of hollow cup motors.

These are the advantages and disadvantages of coreless hollow cup micro motors. For more information about micro DC motors, please continue to follow WKX Motor.