How are micro gear motors applied in the petroleum industry?

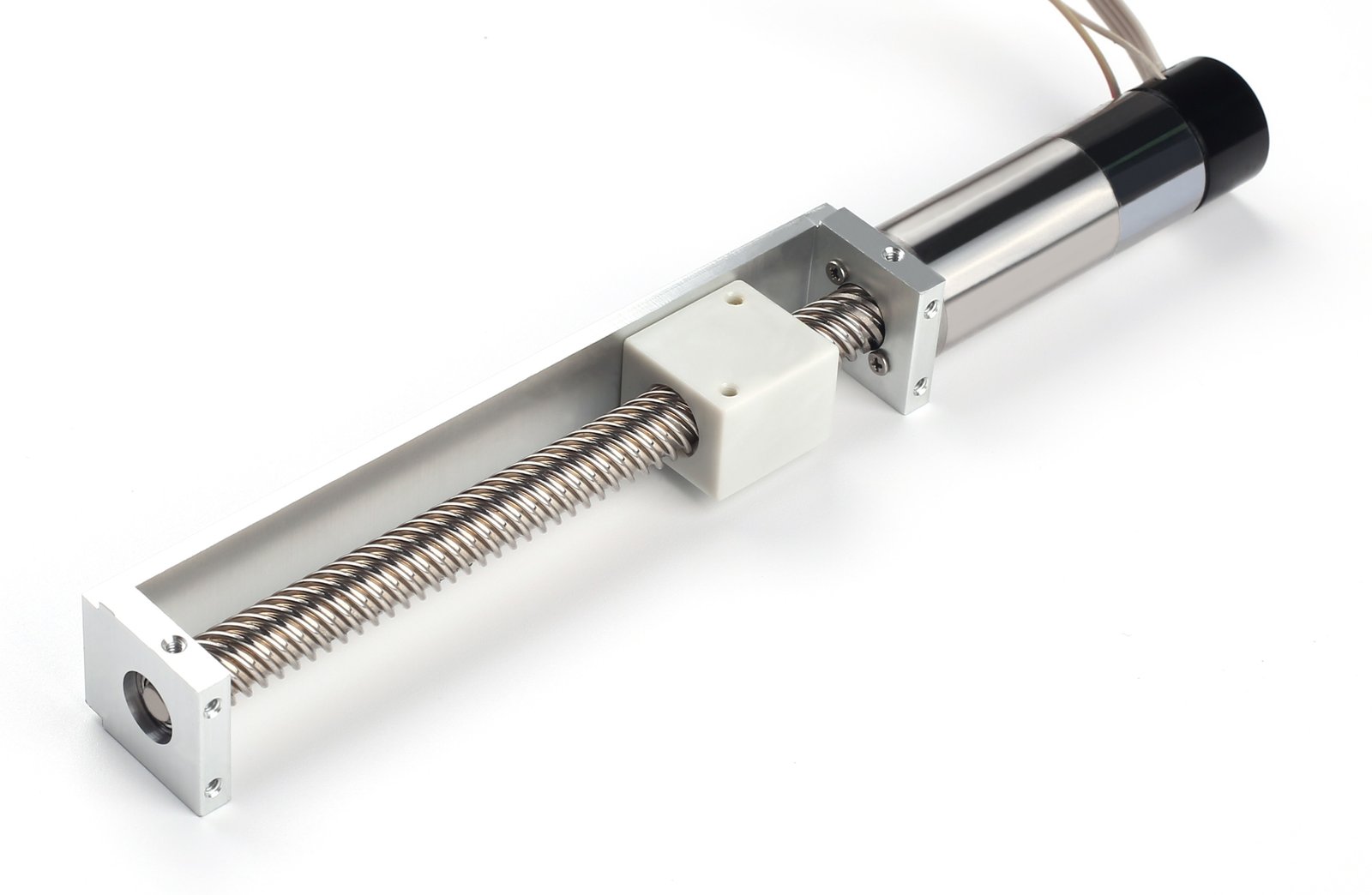

WKX is a comprehensive enterprise integrating the research, development, production, and sales of micro DC motors. Among these products, micro gear motors, as a driving device used to reduce speed and increase torque, are applied in various industries. Today, WKX will briefly explain the applications of micro gear motors in the petroleum industry.

Due to the unique nature of petroleum exploration and extraction, the requirements for micro gear motors are relatively high. Typically, micro gear motors need to operate normally in high-temperature environments (withstanding temperatures above 175°C), provide high torque output (above 10N·m), and withstand harsh downhole conditions, such as high temperature, high pressure, corrosion, and oxidation.

Generally, these gear motors use low-current input and are driven by brushless motors without Hall sensors. The purpose is to prevent damage to Hall sensors in high-temperature environments. Due to varying downhole measurement requirements, the output speed and torque of the gear motors differ. For example, in multi-arm caliper tools, the gear motor needs to achieve low speed and high torque, requiring a precision gearbox. In core sampling equipment, the gear motor must withstand high temperature and pressure while providing high torque output at higher speeds for fast, safe, and accurate performance.

WKX is strategically committed to research and development, emphasizing advanced technology and production techniques. Through industry comparisons and extensive experimental testing data, WKX has designed and developed products such as micro gear motors, coreless motors, and coreless DC motors.