Advantages of Coreless Motors Compared to Iron-Core Motors

Below, WKX will introduce the advantages of coreless motors compared to iron-core motors.

Because there is no iron core, there is no iron loss, resulting in high efficiency.

Because there is no iron core, the coil typically serves as the rotor, with low rotational inertia, making it easy to control and highly efficient.

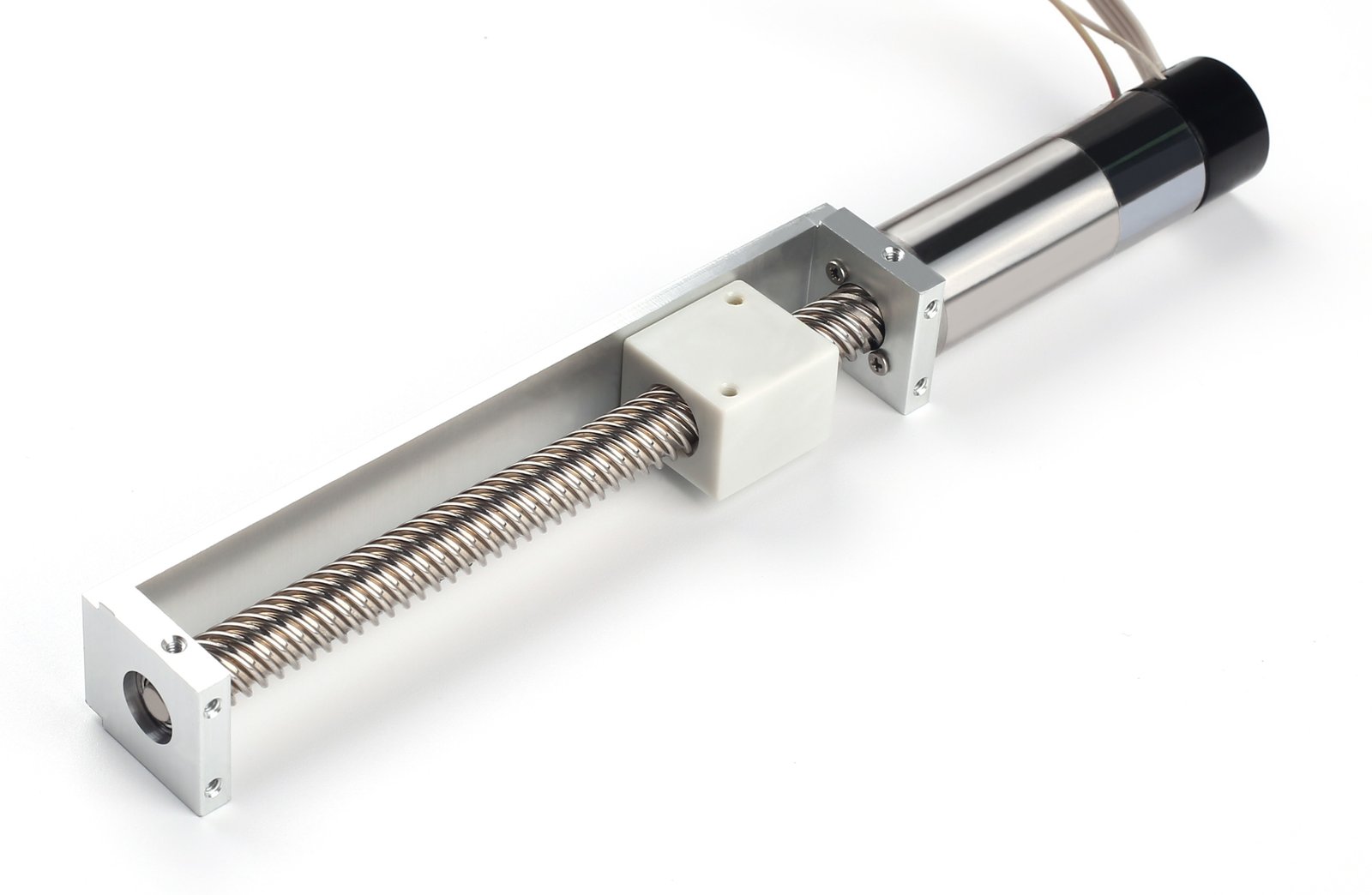

Because there is no iron core, the rotor coil must be made very thin to avoid magnetic flux loss, so coreless motors generally have limited power, typically up to a few hundred watts.

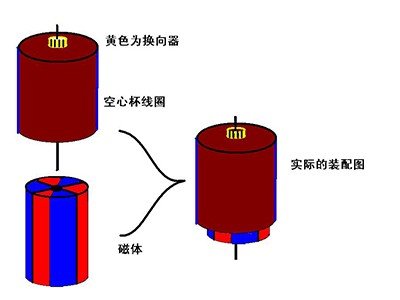

The coil resembles a cup, hence the name "coreless motor."

Advantages of Coreless Motors Compared to Iron-Core Motors:

1. Higher energy conversion efficiency (a measure of energy-saving characteristics): Efficiency is generally above 70%, with some products reaching over 90% (compared to 15-50% for ordinary iron-core motors).

2. Rapid activation and braking, with extremely fast response times; the mechanical time constant is less than 28 milliseconds, with some products achieving within 10 milliseconds. In the recommended high-speed operating range, speed regulation is highly sensitive.

3. Reliable operational stability with strong adaptability, capable of controlling its own speed fluctuations within 2%.

4. Low electromagnetic interference, utilizing high-quality brushes and commutator structures, with minimal commutation sparks, eliminating the need for additional anti-interference devices.

5. High energy density; compared to iron-core motors of the same power, its weight and volume are reduced by 1/3 to 1/2, and corresponding parameters such as speed-voltage, speed-torque, and torque-current exhibit standard linear relationships.

WKX MOTOR specializes in the research and production of coreless motors, focusing on coreless brushed, brushless, geared, and servo motors.