Comparison of Spur Gearboxes vs. Planetary Gearboxes

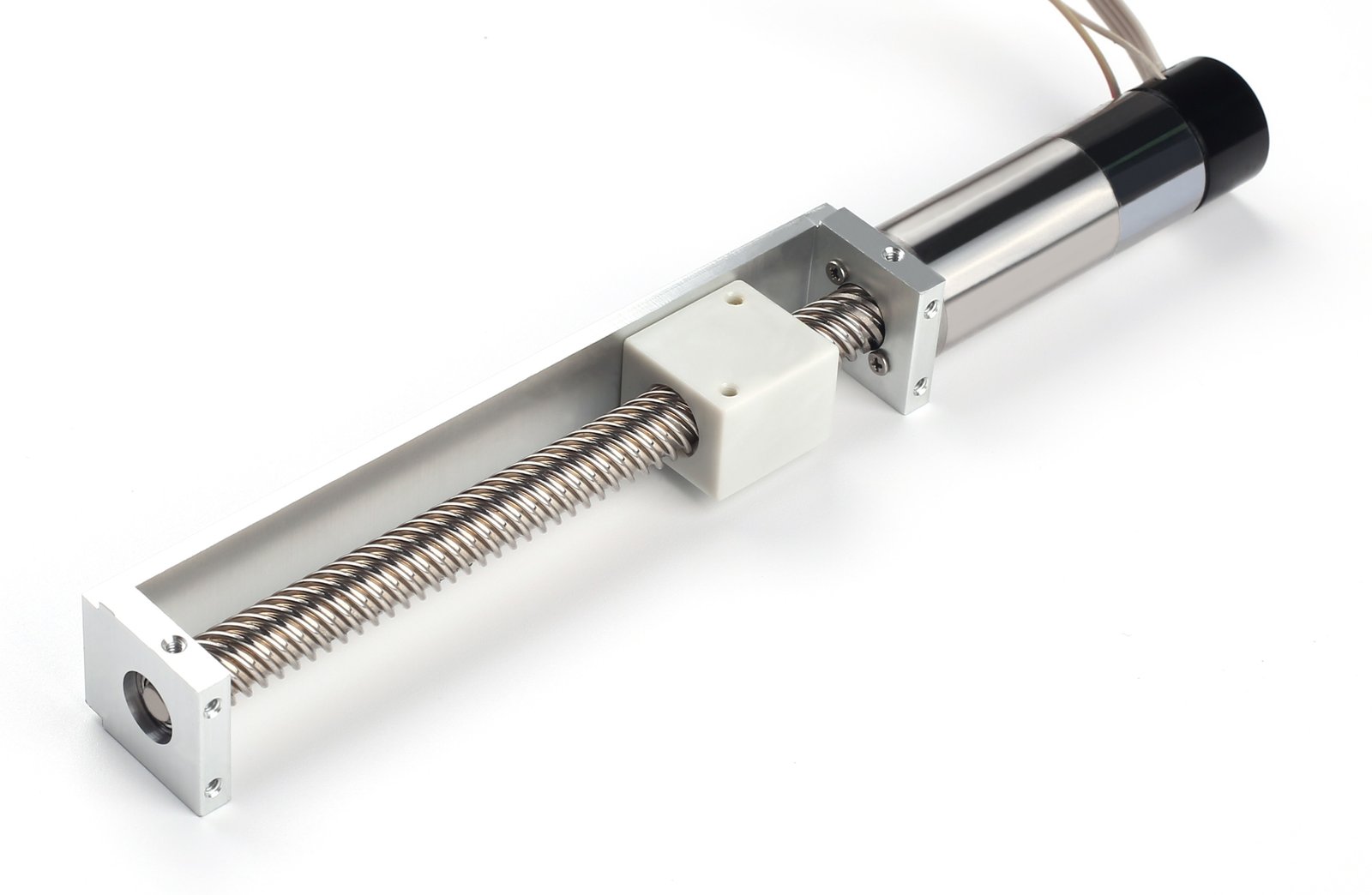

The spur gearbox is designed with two gears (single stage) working together to increase the torque potential of the drive motor. Each gear in the transmission chain of a spur reducer bears the entire torque load, so these reducers are used in applications specifying lower torque. Backlash is also a common issue when using gearboxes. Backlash depends on the shape and precision of the gear teeth as well as the precision of the gear mounting arrangement. Efficiency is also affected. The interaction between these two—backlash and efficiency—is that increased mechanical clearance between gears favors efficiency but is detrimental to backlash. Generally speaking, spur reducers are the simplest and cheapest of the two devices.

The planetary reducer has a more complex design.

The input shaft drives the central (sun) gear, which then rotates the surrounding (planet) gears, allowing each planet gear to transmit torque in perfect synchronization with the other planet gears. For planetary gearboxes, the torque load is shared among multiple "planet" gears, resulting in greater torque output capability and reduced stress on each individual gear.

Both types of gearboxes are made from various metals and plastics, including brass, steel, nickel steel, and other alloys. Important design factors include the size of the gears and the number of teeth on each gear. This determines the gear ratio, which dictates the output torque and shaft speed.

With proper machining, you can achieve the same backlash from both spur and planetary gearboxes. For standard gears, this range is 1 to 2 degrees. Planetary gearboxes and spur gearboxes can provide up to 90% efficiency for single-stage devices. (All gearboxes can include multiple stages, but this approach also increases the length of the device.) The reduction ratios for spur and planetary gearboxes range from nearly 1:1 to thousands to one.

Generally speaking, spur reducers are quieter than planetary reducers. On all gearboxes, noise increases at higher speeds, but note that noise is a function of tooth profile, tooth interaction, and materials used. Steel cut gears are the most durable, making them ideal for high-torque applications, while porous sintered gears are better suited for retaining lubricants. (Lubrication is a factor when considering service life.)

In most cases, the choice of which reducer type to use relates to the torque capacity of the reducer, while the selection of reduction ratio is primarily related to the input speed limitations required by the application. Whether spur or planetary, speed mainly depends on the design purpose of the device. Tooth profile design is an optimization and compromise process that affects speed, torque, efficiency, and backlash, as well as noise levels—and all combinations of these factors.