What are the basic testing methods for coreless motors?

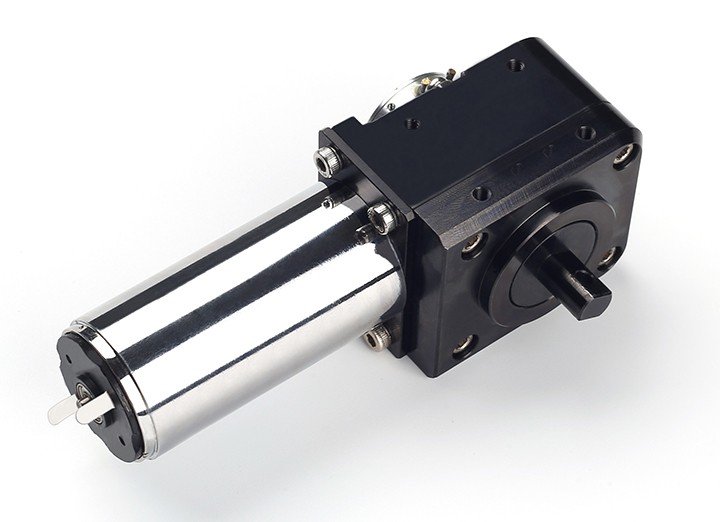

Generally, coreless motors purchased from suppliers must be tested before they can be used in products or put into production. What are the general operational procedures for testing coreless motors using a coreless motor tester? WKX MOTOR shares the following details:

1. Testing Motor Speed In actual operation, determine whether the coreless motor to be tested is a three-pole or five-pole DC motor and check if the M3 indicator light corresponds to the appropriate state. Additionally, when selecting M0 mode, ensure that the allowable deviation values are symmetrical, with the midpoint between the upper and lower limits reflecting the typical value for that motor model.

2. Insulation Resistance Testing Insert the red and black test leads into the red and black insulation testing ports, respectively. Connect the clip to the motor housing and one pole of the coreless motor to check if the insulation level exceeds the limit, as indicated by whether the over-limit indicator light is on.

3. Waveform Output Display Connect the oscilloscope’s signal lines to the waveform output and signal input terminals of the oscilloscope. By adjusting the oscilloscope, you can observe the motor’s current waveform. Generally, this oscilloscope cannot be used to measure the axial play (commutation) of the coreless motor or the internal resistance of the motor when the axial play is at its maximum.

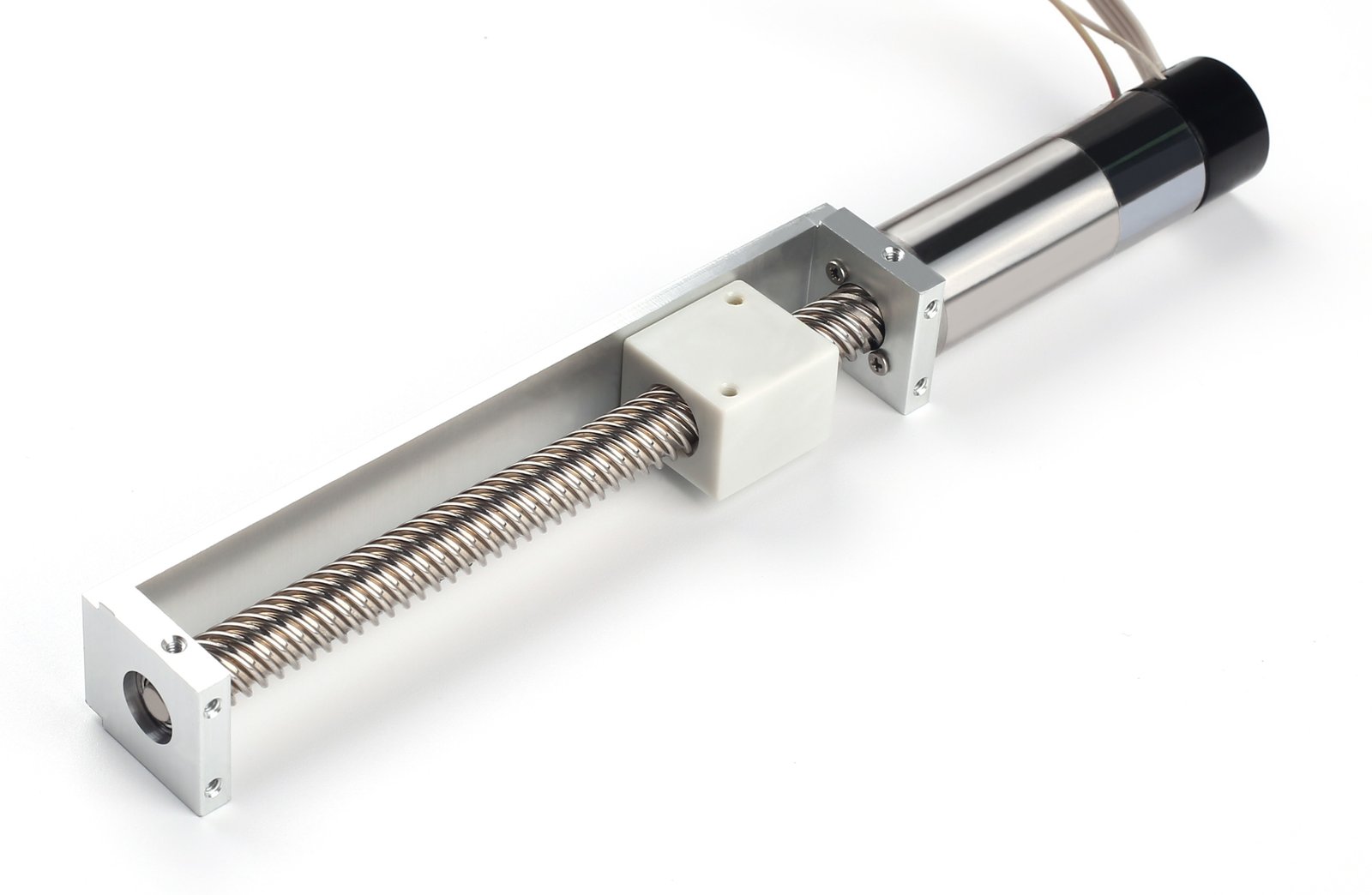

Shenzhen WKX MOTOR Co., Ltd. specializes in the research, development, and production of coreless motors, including coreless motors, medical coreless motors, coreless brushless motors, and gear motors.