How is speed variation achieved in coreless brushless DC motors?

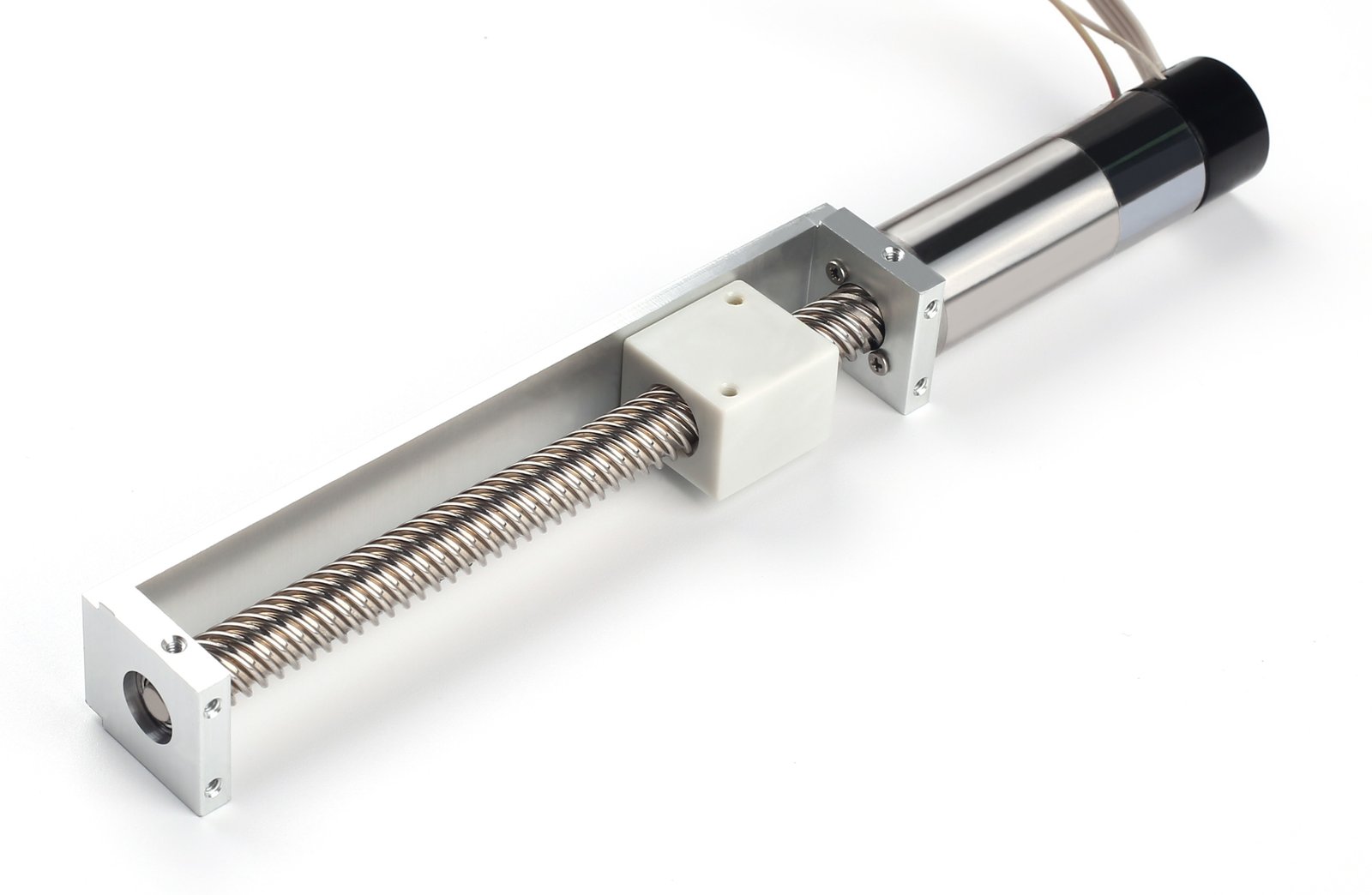

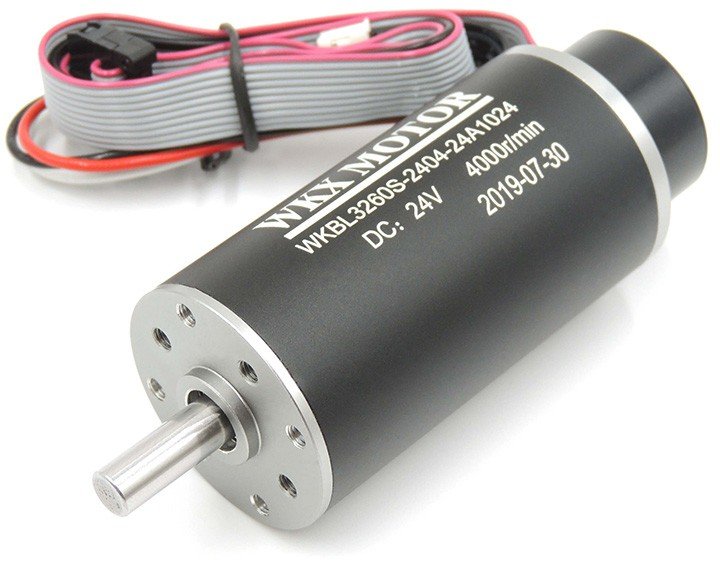

How is speed variation achieved in coreless brushless DC motors? The main characteristics of coreless motors include high efficiency, low energy consumption, low noise, long lifespan, high reliability, servo control, and stepless variable frequency speed regulation (up to the maximum speed). Compared to brushed coreless DC motors, brushless coreless DC motors are significantly smaller in size, simpler to control than asynchronous AC motors, offer high starting torque, and have strong overload capacity.

Based on the working principle of coreless brushless DC motors, we know that DC (brushed) motors can adjust speed by regulating voltage, adding series resistance, or changing excitation. In specific product designs, variations in factors such as the thickness of the motor's enameled wire or the size of the magnet result in different motor speeds. Generally, the most convenient and commonly used method for motor speed regulation is adjusting the voltage. Currently, PWM (Pulse Width Modulation) is the primary method used for speed control. PWM regulates DC voltage through high-speed switching. A longer on-time results in a higher average voltage, while a longer off-time results in a lower average voltage. This circuit adjustment is very convenient. As long as the switching speed is fast enough, the grid harmonics are reduced, and the current becomes more continuous. However, prolonged wear of brushes and commutators, combined with significant current changes during commutation, can easily produce sparks. The commutator and brushes limit the capacity and speed of coreless brushless DC motors, creating a bottleneck in speed regulation.

For coreless brushless DC motors, speed regulation appears to involve only controlling the input voltage. However, the motor's self-controlled variable frequency speed regulation system (equipped with a rotor position detector and other rotor position signal acquisition devices) uses the rotor position signal to control the commutation timing of the variable voltage and frequency speed regulation device. This system automatically adjusts the frequency based on the voltage, making it nearly identical to DC (brushed) motors and highly convenient.

Since the rotor uses permanent magnets, there is no need for special excitation windings. For the same capacity, the motor is smaller in size, lighter in weight, more efficient, more compact in structure, more reliable in operation, and has better dynamic performance.

To achieve optimal product application results, different motor speed regulation methods are adopted based on the characteristics of various products. In solutions for applications such as humidifiers, air purifiers, fans, and more, PWM signal speed regulation is used. By adjusting the duty cycle of the PWM signal, the average voltage across the coreless DC motor is modified, enabling speed regulation while ensuring that the power supply’s output voltage remains constant under changing operating conditions.